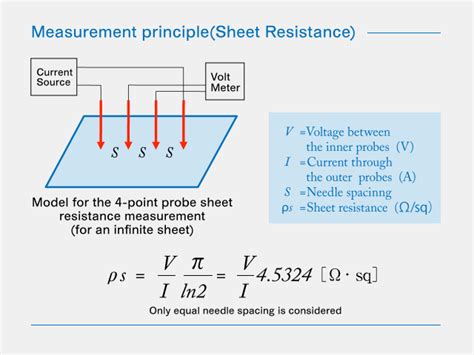

metal sheet resistance Calculate Sheet Resistance Using the Four-Probe Method. Sheet resistance (also known as surface resistance or surface resistivity) is a common electrical property used to characterize . A U-Shape enclosure would work best, as there are fewer seams to weld. NEMA Type 4,4X: We recommend fully welded seams and the use of gaskets . Gaskets are .

0 · what is a sheet resistance

1 · sheet resistance pdf

2 · sheet resistance geometry

3 · sheet resistance diagram pdf

4 · sheet resistance calculation

5 · how to measure sheet resistance

6 · how to find sheet resistance

7 · 4 point sheet resistance

$299.99

Calculate Sheet Resistance Using the Four-Probe Method. Sheet resistance (also known as surface resistance or surface resistivity) is a common electrical property used to characterize .

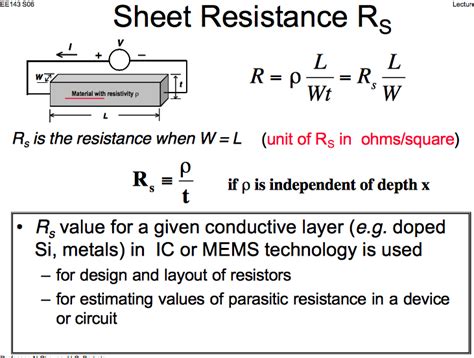

Sheet Resistance Rewrite the resistance equation to separate (L / W), the length-to-width ratio . which is the number of “squares” N from R , the sheet resistance = (σ n t)-1 = R (L/W) = R N .Sheet Resistance Calculator. The SURAGUS layer calculator also known as rho tool is able to calculate various physical parameters of single layer systems and double layer systems. .

Heat-resistant metals, the majority and exemplary among extreme heat-resistant materials, showcase unique properties that make them indispensable in high-temperature applications. These metals come with exceptionally high melting points and remarkable resilience in extreme conditions, providing critical solutions in a variety of demanding .

The sheet resistance was measured by cutting the samples with a razor blade so an electrically isolated narrow strip of paint of length L and width W was created. Again, the resistance of this .For a more complete discussion of direct current sheet resistance, go to our page on this topic. In summary, for direct current, the sheet resistance is calculated from the metal resistivity and thickness: Sheet resistance and sheet .the sheet resistance before and after etching or polishing processes, for example. Choosing the Appropriate Technique The R50-4PP has a maximum sheet resistance of 200MΩ/sq., which makes it ideal for the thinnest of metal films. For very .

Sheet resistance (also called sheet rho) Bulk resistivity; Conductivity; Layer thickness; SURAGUS develops and manufactures non-contact measurement devices which are able to measure the sheet resistance, resistivity, conductivity and layer thickness on thin films. The calculator converts theoretical values based on the laws of physics. The effect of metal sheet resistance on capacitance measurements of Schottky barriers is investigated through modelling. The calculations show that when the capacitance is determined by conventional ac impedance measurements, the value obtained is less than the true capacitance when the metal sheet resistance is high.sheet resistance is commonly used in describing the properties of films and layers in integrated circuits, solar cells, and other nanostructures. . Metal line resistance refers specifically to the resistance encountered by electric current as it travels through a line made of metal. This is especially important in microelectronics where .

Sheet metal screws offer a convenient fastening solution for metal sheets. They feature a threaded shank with a pointed tip. . Keep in mind that while sheet metal screws can be used with wood, wood screws can’t be used with metal. #4) Poor Corrosion Resistance. Another common myth is that sheet metal screws offer little or no resistance to . The metal sheet resistance decreased a little upon annealing; the value RS - 10.3 S2/p was used in the calculations. The contact resistivity values measured after annealing are reported in Table 1. As a result of annealing, the contact resistivity of TiN increases by a factor _ 2 on n + substrates, and decreases by a factor of - 3 on p . i dont find any relationship between sheet resistance and metal spacing. sheet resistance is a property of that particular metal. it is fixed by foundry people. where as metal spacing is fixed by a physical design team of an ASIC . Jun 14, 2006 #8 J. jemmy Junior Member level 1. Joined Jun 7, 2003 Messages 18 Hi, If we are using a 0.18u TSMC library does the library file have the spec for the current handling capability of a layer in A/m and also the sheet resistance so that we can do the manual calculation of the IR drop.If no then where do i get this info from?

library tt_res in 80nm hspice library there are three the metal 1 resistance model: rm1l rm1s rm1w rm1l: metal 1 with W/S = 0.108/0.324 rm1s: metal 1 with W/S = 0.108/0.108 rm1w: metal 1 with W/S = 0.324/0.162 what does W/S mean? For sheet resistance measurement, the EC method is restricted to no less than about 100 nm of metal thickness (or about 10 Ω/sq., depending on the type of metal), due to the minimal eddy currents generated by extremely thin metal films.

what is a sheet resistance

Sheet resistance of metal lines is mainly affected by critical dimension (CD), etch depth, and chemical mechanical planarization amount in damascene process. Therefore, these factors must be stably controlled in order to stabilize the sheet resistance of metal lines. Especially the etch depth, which is sensitive to the pattern density and the .As you can see from the plot below, from 1 GHz on up you have over five skin depths. So you have achieved the "maximum RF sheet conductivity" of the metal at any microwave frequency. Below is what that means in terms of RF sheet .Our guides include: Product Guide – Provides an inspiring overview of the different color solutions that Steelscape offers.; Color Design Guide – A comprehensive overview of modern color trends and finish options for metal . The sheet resistance affects signal attenuation, power loss, and the overall efficiency of the RF component or circuit. Cadence AWR Software and RF Sheet Resistance. Understanding and effectively managing RF sheet resistance is crucial for advanced RF circuit design. To take your designs to the next level, explore Cadence AWR software. This .

10 3 in phillips pan-head sheet metal screws

The DC resistance of a metal sheet is given by R=ρ*L/A where ρ is the resistivity, L the lenght along with the current flows and A is the cross-section. Is the sheet has thickness T, and width W then A=W*T from which: R=ρ*L/(W*T). Now we can define the sheet resistance as Rs=ρ/T so that the total resistance can be written as: R=Rs*L/W.Many façades are made from high-quality sheet metals, which enhance durability and contribute to their weather-resistant properties. HVAC In maintaining good indoor air quality, selecting the right materials for the heating, ventilation, and air conditioning (HVAC) system is crucial to ensuring the desired comfort and health of your building.

Heat resistance การทดสอบการต้านทานความร้อน ECO PLUS PU FOAMการทดสอบการต้านทานความร้อนของฉนวนกันความร้อน ECO PLUS PU FOAM เปรียบเทียบกับหลังคา Metal Sheet .

1/16th sheet metal

sheet resistance pdf

Sheet Resistance of Metal Sheets. Metal sheets consist of aluminum, brass, copper, steel, tin, nickel and titanium. Very few decorative sheets consist of silver or gold. There are catalyst sheets consisting of e.g. platinum. Most common materials are stainless steel, e.g. 304, and aluminum, e.g. 1100-H14, 3003-H14, 5052-H32, and 6061-T6.The sheet resistance value of the 10 nm Au film deposited on the MoS2 surface at 100 °C is also shown in the figure. . Thin metal films find broad application in advanced as well as every-day . Metal Supermarkets is the world’s largest small-quantity metal supplier with over 125 brick-and-mortar stores across the US, Canada, and United Kingdom. We are metal experts and have been providing quality customer service and products since 1985. At Metal Supermarkets, we supply a wide range of metals for a variety of applications.

What Is Sheet Resistance? The resistance between the contacts is L / W has no units ρ / t should have units of ohms But . . . R ≠ ρ / t! Sheet resistance R sh = ρ / t (ohms / square) Resistance independent of the size of the square ohms W L A t L R ρ ρ = = R = (R sh )x (numberof squares) [ohms] W L . t . ρ . 5 squares . R. sh

Tungsten: This component increases the heat resistance of the alloy steel, which raises the melting point. It also improves the structural composition of the steel. Chromium: . This sheet metal substance has iron alloyed with carbon to give it a high level of durability. A manufacturer can select steel with low, medium, or high carbon content . The Basics of Scratch-Resistant Metal Surfaces. Custom sheet metal fabrication is the first step toward creating a scratch-resistant metal surface. Alpine can fabricate any type of metal including aluminum, tin, and copper. However, most commercial building owners in search of durable design materials will choose galvanized steel sheet metal .the sheet resistance before and after etching or polishing processes, for example. Choosing the Appropriate Technique The R50-4PP has a maximum sheet resistance of 200MΩ/sq., which makes it ideal for the thinnest of metal films. For very .

sheet resistance geometry

A usinagem CNC de precisão foi além, aumentando a precisão e agilizando o processo de fabricação. Este guia completo explicará todos os detalhes sobre a usinagem CNC de precisão, incluindo suas aplicações e processos.

metal sheet resistance|how to find sheet resistance